Backstory

A Tool for Addressing Systemic Disruptions

MIT’s Sloan School of Management is globally renowned as one of the top business schools, where Dr. Steve Spear teaches cutting-edge methodologies. See To Solve was created to enhance process mapping and alert signaling in complex systems and service chains, where efficiency and performance are critical.

Key Insight

Dr. Steve Spear’s Impact on See To Solve

Dr. Steve Spear, Senior Lecturer at MIT Sloan, plays a pivotal role in the story of See To Solve. A recognized researcher, author, and award-winning expert on high-performance systems, Dr. Spear’s groundbreaking work—such as the acclaimed publication “Decoding the DNA of the Toyota Production System”—has significantly shaped the understanding of organizational efficiency. His expertise informed the foundational principles of See To Solve as a tool for continuous improvement and real-time problem-solving.

Strategy & Approach

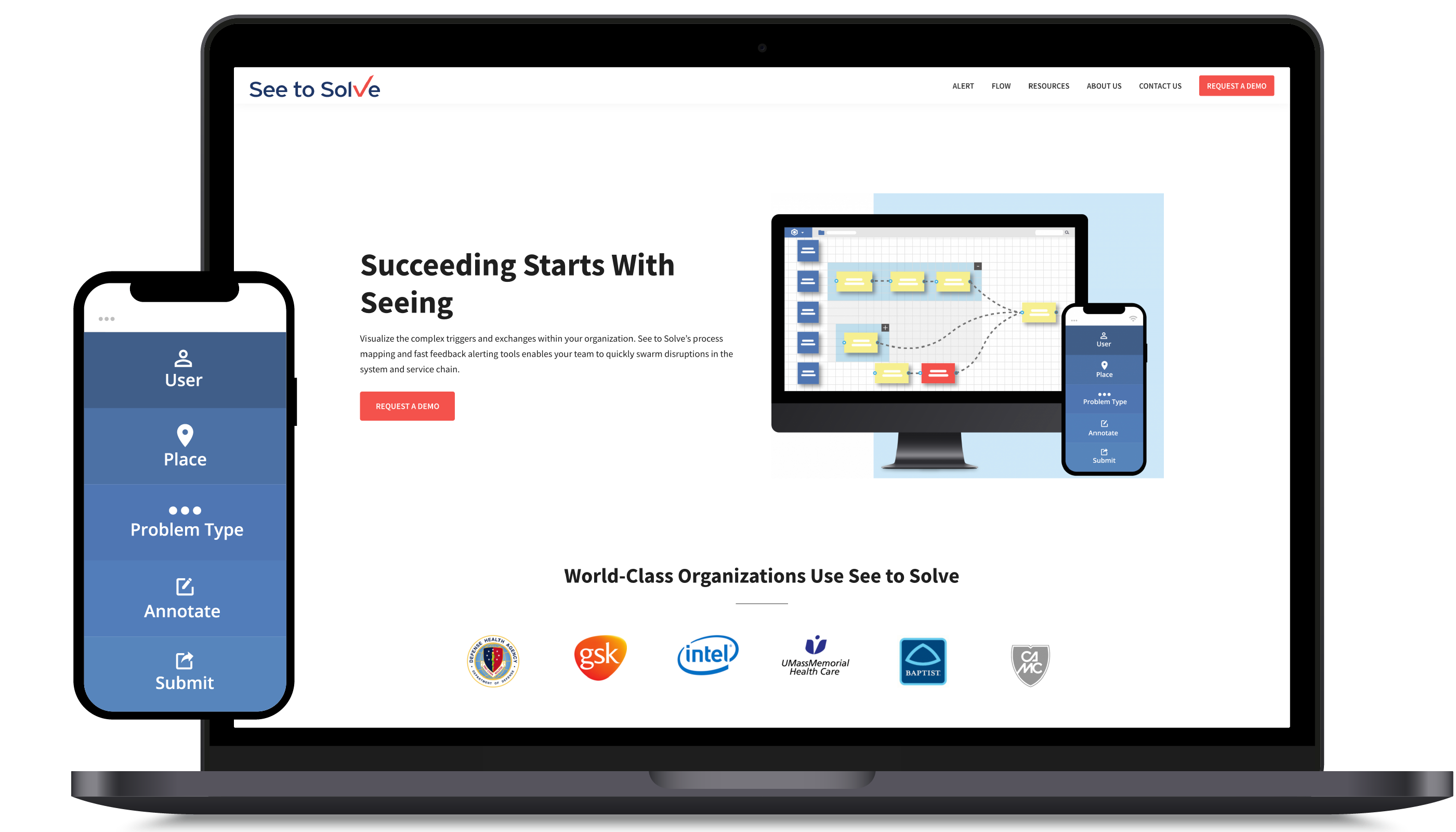

Elevating Product Visibility

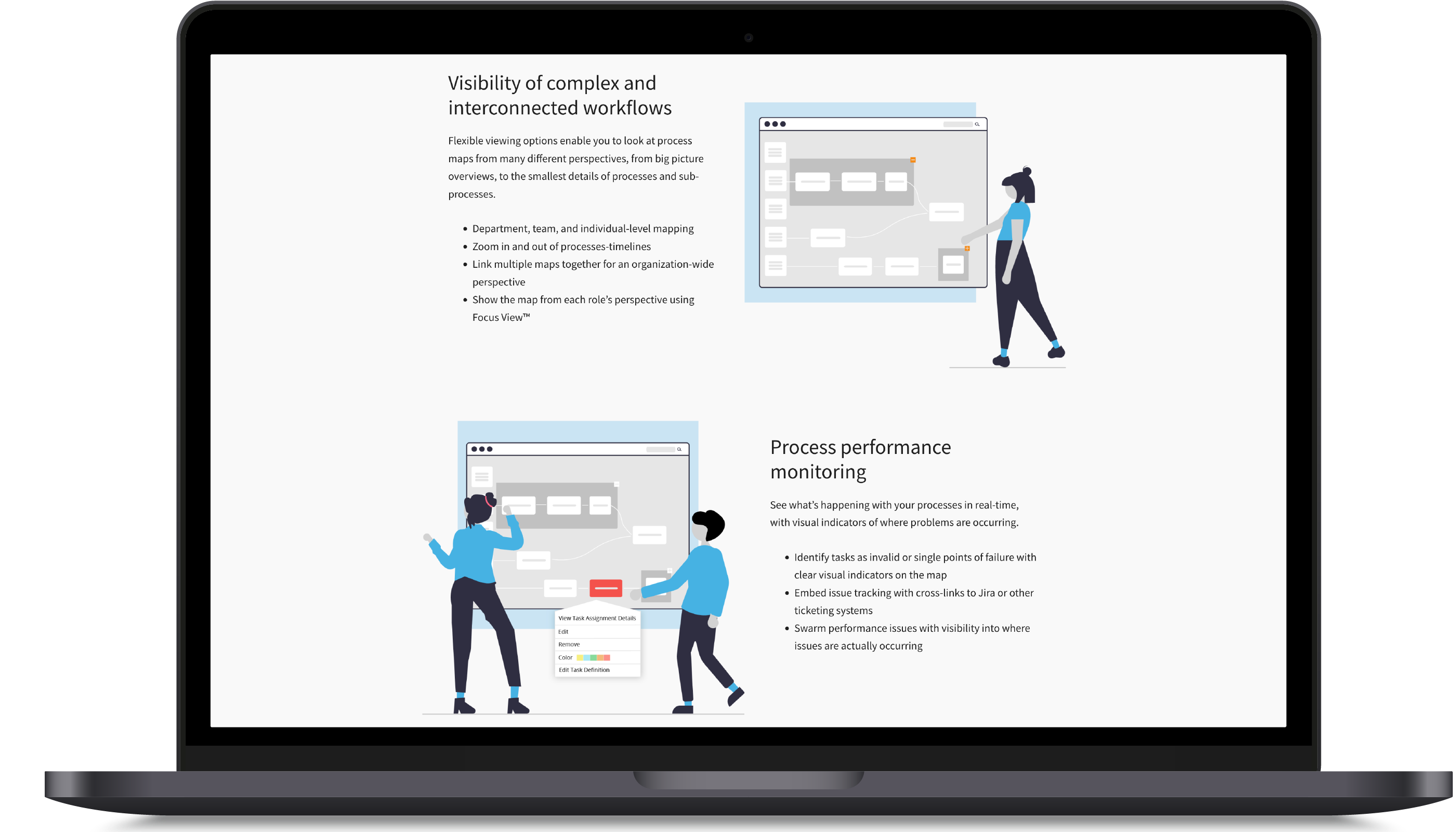

See To Solve features two core products: a primary alert system and a collaborative process mapping tool. However, the process mapping tool—which served as an essential gateway product for users—was underrepresented on the previous website. Nearly every organization adopting the alert system first used the mapping tool, highlighting its importance in the adoption journey.

For the redesigned website, we focused on showcasing both products equally while emphasizing their distinct benefits.

Core capabilities highlighted:

- Collaborative Process Mapping: Providing a blueprint to achieve objectives efficiently.

- Real-Time Alert System: Enabling teams to address issues before they escalate.

- Continuous Improvement Culture: Teaching organizations to integrate improvement into their workflows.

- Step-by-Step Problem Solving: Illustrating how See To Solve supports problem reporting, rerouting, and generating actionable insights.

Key Insight

The Andon Cord Concept

See To Solve draws inspiration from Toyota’s iconic Andon Cord—a physical rope along the assembly line that any worker could pull to halt production when an issue was detected. This method encouraged teams to swarm problems as they arose, fostering a culture of proactive issue resolution.

By translating this concept into a digital context, See To Solve empowers organizations to achieve similar results, instilling “autonomic” behavior patterns for problem-solving and maintaining operational excellence.

Outcome

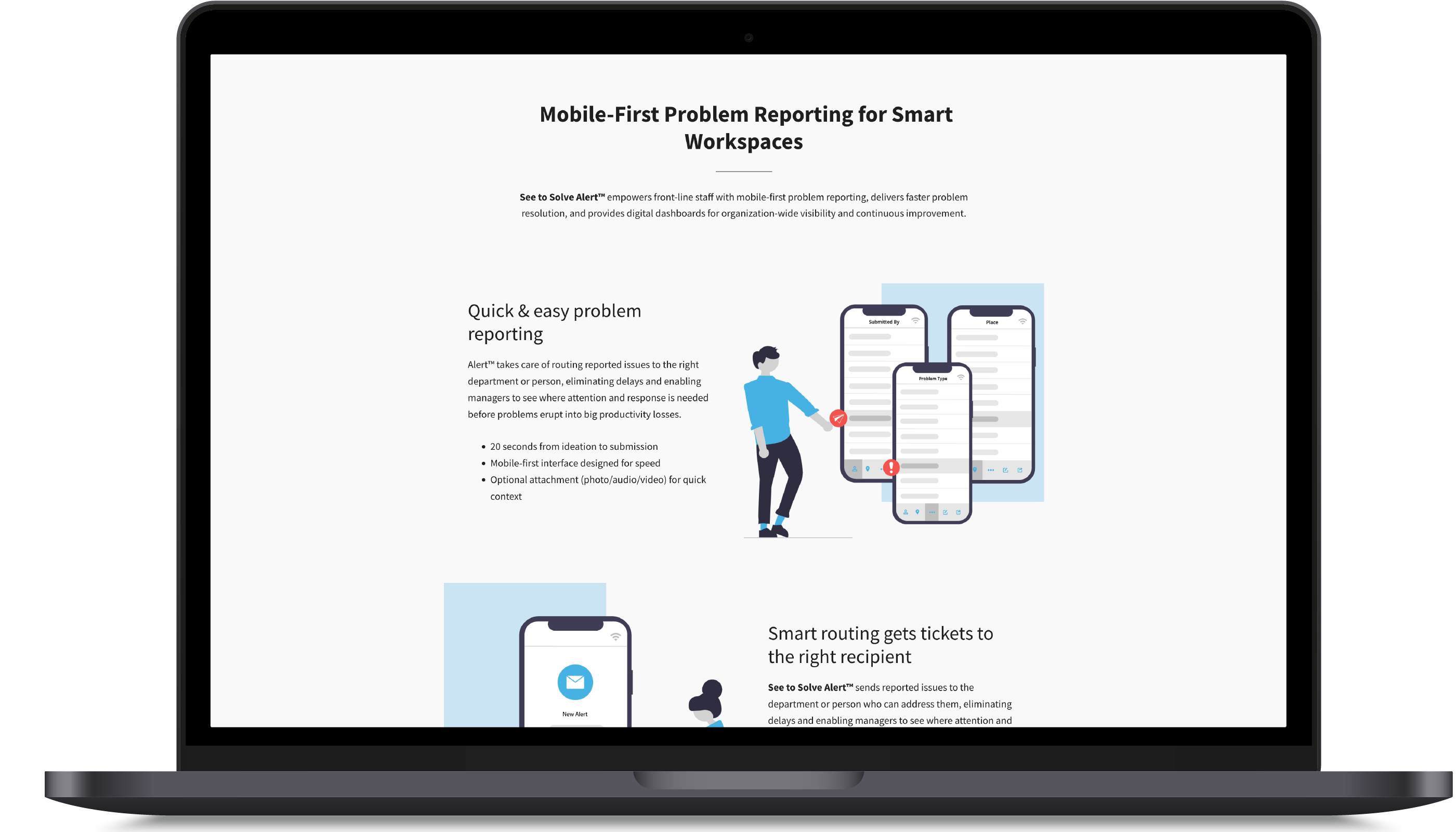

See To Solve Alert: The Portable Andon Cord

We positioned See To Solve Alert as a mobile-first reporting system designed for smart workspaces. It empowers frontline staff with real-time problem reporting, enabling faster resolution and preventing small issues from becoming significant productivity challenges.

In the spirit of Toyota’s production system, Alert acts as a “portable andon cord,” helping organizations identify areas that need attention before disruptions spread. With its redesigned website and clearer messaging, See To Solve now communicates its value proposition effectively to potential customers, reinforcing its role as an essential tool for high-performance systems.